Choosing Custom Metal Grates for Municipal Applications

Morgan’s Welding offers customizable municipal metal grates. This article covers the factors you need to consider when customizing yours.

Morgan’s Welding offers customizable municipal metal grates. This article covers the factors you need to consider when customizing yours.

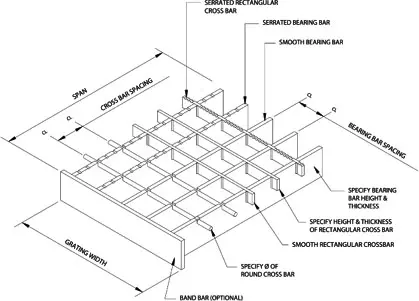

Morgan’s Welding offers customized metal grates that can be used in a wide variety of municipal applications, ranging from pedestrian walkways to drainage systems. When designing your custom grating, you’ll want to consider several factors, including material properties, load requirements, environment, and installation needs.

Morgan’s Welding specializes in manufacturing custom metal grates primarily from carbon steel, the most common material option for grating due to its high strength-to-weight ratio, durability, and cost-effectiveness for heavy-duty applications. Additionally, carbon steel’s high modulus of elasticity minimizes deflection under load, providing a more stable surface for pedestrian and vehicular traffic.

We can also reinforce grating with hot-dip galvanizing to improve corrosion resistance when used in outdoor applications.

Load is heavily influenced by bar spacing (closer spacing increases load capacity and minimizes flexing under pressure), bar size/thickness (thicker and deeper bars offer better strength for concentrated loads), and bearing depth (deeper bearing bars provide more strength but need structural support).

If the metal grating has to support vehicular loads regularly, you’ll want to ensure compliance with the American Association of State Highway and Transportation Officials (AASHTO)’s HS-20 designation.

Morgan’s Welding offers load tables to help you calculate potential load per grating type.

Consider whether the grating will be surface-mounted on a support structure or recessed into a frame or trench. Bolted grating is easier to remove and maintain, so it’s ideal for drainage systems and service access points. Comparatively, welded grating is permanent, high-strength, and better for heavy-traffic areas and structural walkways.

Every application is unique—if you need help designing custom grating, please contact Morgan’s Welding. We can work with existing drawings or help you create renderings/drawings based on application requirements. Please visit our website to get started.