The Most Common Applications for Heavy-Duty Steel Grates

Municipalities rely on heavy-duty steel grating for many applications, ranging from drainage to maintenance access. Learn more!

Municipalities rely on heavy-duty steel grating for many applications, ranging from drainage to maintenance access. Learn more!

Municipalities across the United States rely on thick, heavy-duty steel grating to improve safety for pedestrians, protect infrastructure during severe weather events, and ensure maintenance is easier and safer for technicians.

Heavy-duty grating, as compared to light-duty, is critical for municipal applications because they are designed to withstand significant loads, such as vehicles, and harsh conditions without degrading.

In this article, we’ll explore a few of the ways that municipalities rely on heavy-duty grating.

U.S. cities that experience frequent heavy rainfall periods need to have solutions to prevent flooding. Heavy-duty steel grating supports wastewater operations by providing reliable draining. Many drains are located in streets and parking lots, so they are subjected to heavy traffic. By using heavy-duty grating, the risk of it collapsing or deforming under these heavy loads is minimized, thereby reducing accidents and maintenance costs.

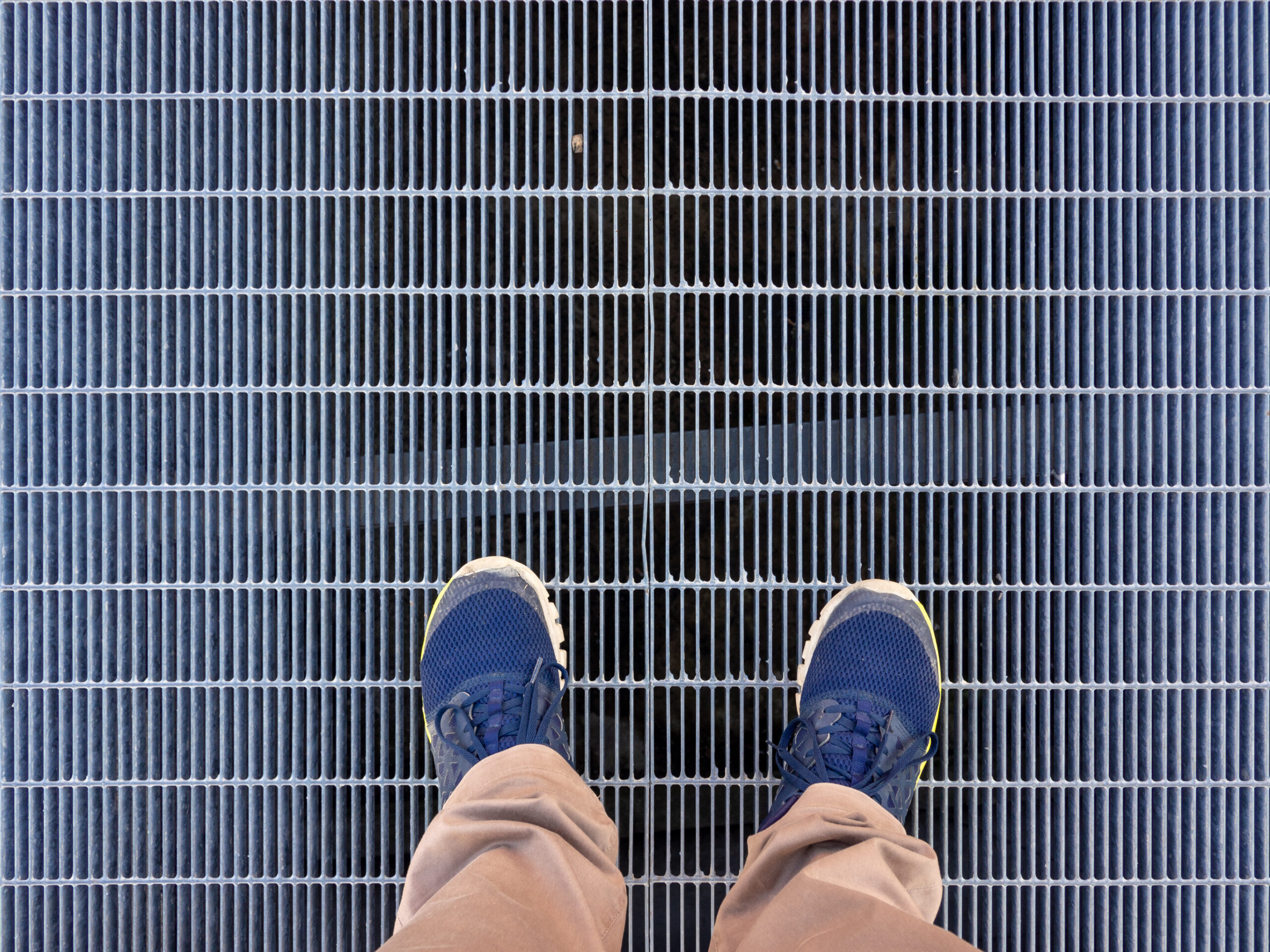

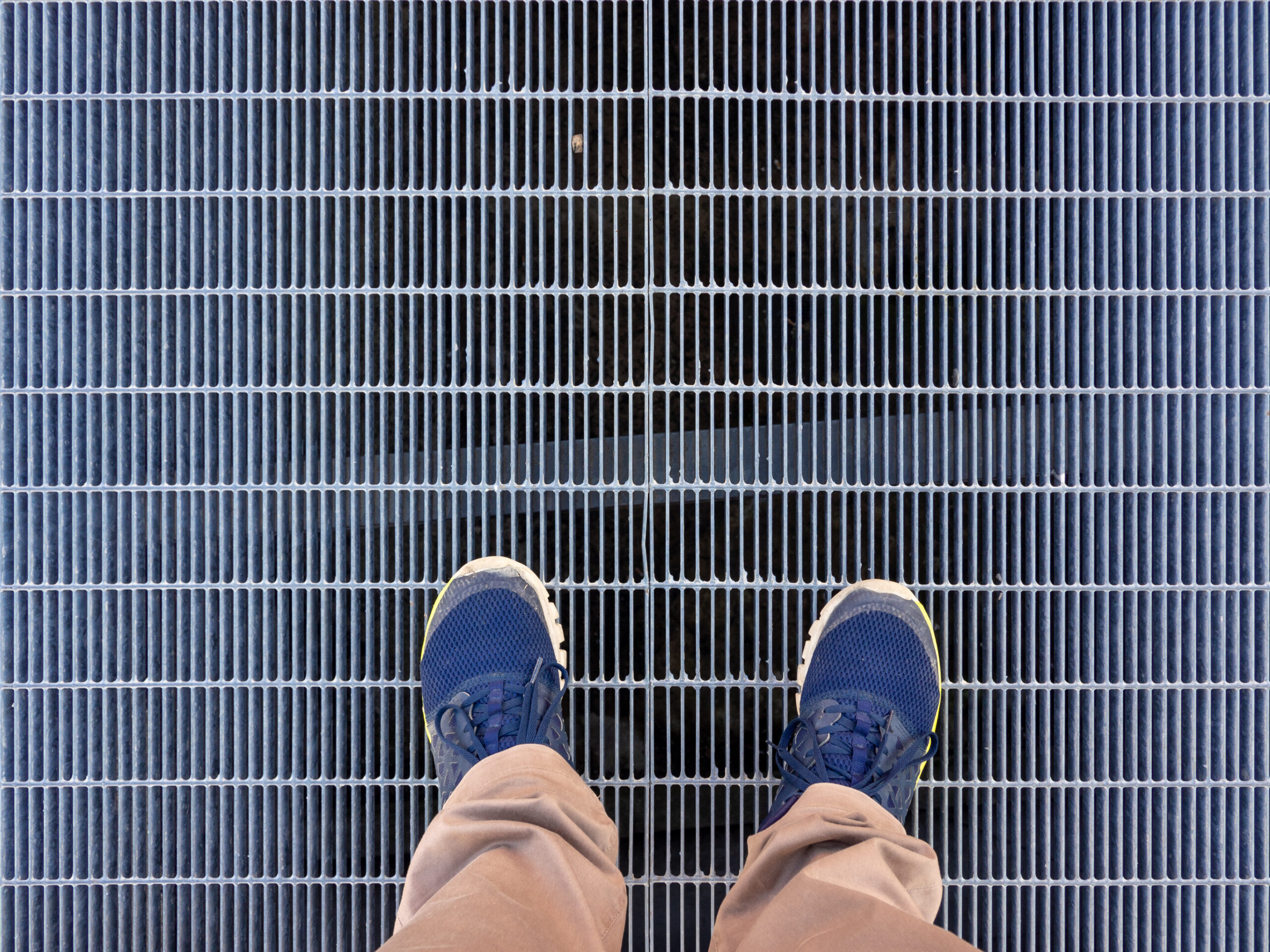

Access covers are commonly in areas that experience both pedestrian and vehicle traffic (sometimes unexpectedly). When made with thicker bars and deeper profiles, the grating can safely handle larger vehicles without failing. Grating, as opposed to a solid access cover, also allows for better air circulation to prevent hazardous gas buildup. The open design also reduces water pooling and allows workers to perform inspections without removing the covers.

It’s not uncommon for large groups to crowd together as they wait for the subway or train. When this happens, the platforms they stand on must withstand that increase in load without failing, which could result in a devastating, life-or-death situation for those pedestrians.

Additionally, when the subway or train arrives, with it comes intense vibration that would cause weaker structures to fail. And, in areas that experience all four seasons, those platforms can become slick with snow, slush, or ice. The open design allows snow, slush, and ice to melt through, improving safety.

Most walkways (within cities) will use steel grating over highways and waterways, on boardwalks, near buildings, and in any area that experiences high foot traffic. The purpose of the grating is threefold: 1) To provide easy maintenance access to underground utilities, while 2) not obstructing the walkway, and 3) to allow stormwater to drain instead of pooling.

Heavy-duty grating, in particular, is preferred for these applications because it withstands the constant abuse from delivery carts, unauthorized vehicle access, strollers, etc., and in waterfront environments, can prevent slip-and-fall incidents.

Morgan’s Welding has been manufacturing steel grating for nearly five decades. We know how critical reliability and performance are in municipal applications. That’s why we offer both standard and custom options to meet specific application requirements. Our gratings are welded to improve strength and can be made from carbon steel or special alloys (upon request).

Contact us today to learn more about our solutions, or visit our website for more resources.